High-Purity Solvents for PFAS Analysis

1 de July de 2025Maximum sensitivity. Minimum interference.

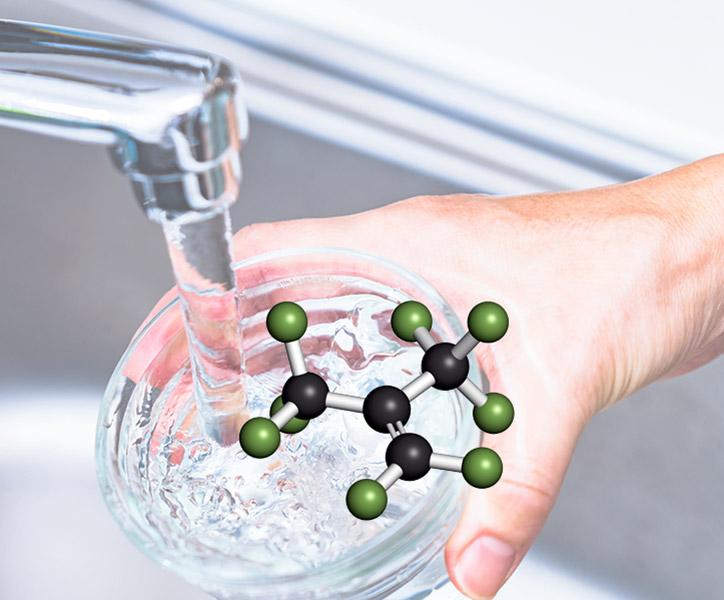

The analysis of PFAS (per- and polyfluoroalkyl substances) has been included in multiple regulatory frameworks and standards, making it essential to detect and quantify them in the relevant matrices, primarily in water, food, and soil.

With this growing regulatory and legislative focus, the demand for precise, interference-free analysis has increased. However, due to the widespread presence of these compounds in everyday life, this has become a significant challenge for analytical laboratories.

PFAS are synthetic chemicals characterized by highly stable carbon–fluorine (C–F) bonds, which have been used for decades in the production of packaging, non-stick coatings, clothing… but are now associated with certain risks to human health.

To address this need, Scharlau presents its new range of high-purity solvents developed specifically for PFAS analysis.

These solvents have been manufactured, purified, and packaged to ensure the absence of per- and polyfluoroalkyl compounds. Since the analysis of these substances is typically performed using LC-MS/MS techniques, they are fully compatible with LC-MS/MS applications.

Nevertheless, due to their properties, neither sample preparation nor the elution of these compounds is straightforward, making the use of specific solid-phase extraction cartridges and chromatographic columns essential.

It is also crucial to pay close attention to the laboratory materials in use, ensuring that samples do not come into contact with plastics that could lead to contamination. For this reason, UCT vacuum manifolds or PFAS-free caps from Macherey-Nagel are emerging as ideal allies in this type of analysis.

Considering all these aspects, developing a robust analytical method remains a significant challenge. In this regard, application notes from UCT and Macherey-Nagel offer valuable guidance for method development and validation.

For more information, contact us at helpdesk@scharlab.com.

FAQs

Per- and polyfluoroalkyl substances (also known as PFAS or forever chemicals) are highly resistant synthetic compounds made up of chains similar to fatty acids, but with carbon–fluorine (C–F) bonds that make them extremely stable. This chemical structure gives them strong persistence in the environment and in living organisms (bioaccumulation), raising concerns about their potential health effects even at extremely low levels of exposure.

Analyzing PFAS is difficult because:

- They are widespread in the environment, found in complex matrices such as water, soils, or food, which interfere with measurements.

- Their extreme chemical stability means they do not easily degrade during analysis.

- They can enter as background contaminants from laboratory materials, solvents, or plastics.

- They require highly sensitive techniques such as LC-MS/MS, where even trace amounts can compromise results.

For these reasons, PFAS analysis demands the use of high-purity solvents and fluoropolymer-free materials to ensure reliable and reproducible data.

PFAS have been used for decades across numerous industrial and consumer sectors due to their water-, oil-, and heat-repellent properties.

Some of the most common products include:

- Non-stick cookware and kitchen utensils coated with PTFE.

- Waterproof and stain-resistant textiles such as technical clothing, carpets, upholstery, etc.

- Firefighting foams, widely used in airports, military facilities, and industry.

- Food packaging with coatings that prevent grease or liquid leakage (e.g., microwave-ready containers, coated cardboard, single-use cups, etc.).

- Cosmetics and personal care products, where PFAS are used as finishing agents to improve texture, water resistance, and durability (e.g., long-lasting makeup, lipsticks, mascaras, creams, etc.).

Some products contain PFAS as part of their formulation, while others rely on PTFE-based coatings or films to make them water- or stain-repellent. In both cases, PFAS can be released into the environment, either during manufacturing or throughout the product’s use.

Because high-purity solvents minimise background interference and contamination in highly sensitive techniques such as LC-MS/MS, where even trace amounts of fluorinated compounds can compromise results. The use of ultra-clean solvents ensures more accurate, reproducible, and reliable data, which is essential for the detection of PFAS at very low levels in environmental and food control applications.

When selecting a solvent for LC-MS/MS in PFAS analysis, it is essential to ensure:

- That it is a high-purity solvent certified as PFAS-free.

- That it provides an ultra-low background of contaminants to avoid spectral interferences.

- That it comes with manufacturer specifications confirming the absence of fluorinated compounds.

- That it is chemically stable and compatible with the mobile phases used in chromatography.

The use of validated solvents guarantees accurate and reproducible results, reducing the risk of false positives caused by background contamination.

Use glassware, polypropylene (PP), stainless steel, and PFAS-certified materials.

Avoid materials containing PTFE (Teflon®), FEP, or other fluoropolymers: these can leach PFAS traces and compromise analytical results.

Through blank analyses using LC-MS/MS and by reviewing manufacturer certificates that guarantee the absence of detectable fluorinated compounds.

Rest of the World

Rest of the World