How to improve filtration with Nutsche filters

21 de November de 2023Nutsche filters are an innovative solution to address the challenges inherent to traditional filtration methods, such as Büchner filtration and oven drying.

Nutsche filters are the ideal solution for obtaining high-purity, contaminant-free substances. Filtering, washing, resuspension and drying operations can all be performed in a single unit, thereby reducing operating times and improving product quality.

There is also a stirring feature that can be used for intermediate washings. Depending on the process, the product of interest may be the retained solid or liquid filtrate.

Nutsche filters are designed with high-quality inert materials, so synthetic processes can be carried out safely in a controlled environment at programmed temperatures. Their versatility makes them particularly suitable for a variety of industries, including pharmaceuticals, fine chemicals, and solid-phase synthesis, where liquid–solid extraction is so demanding.

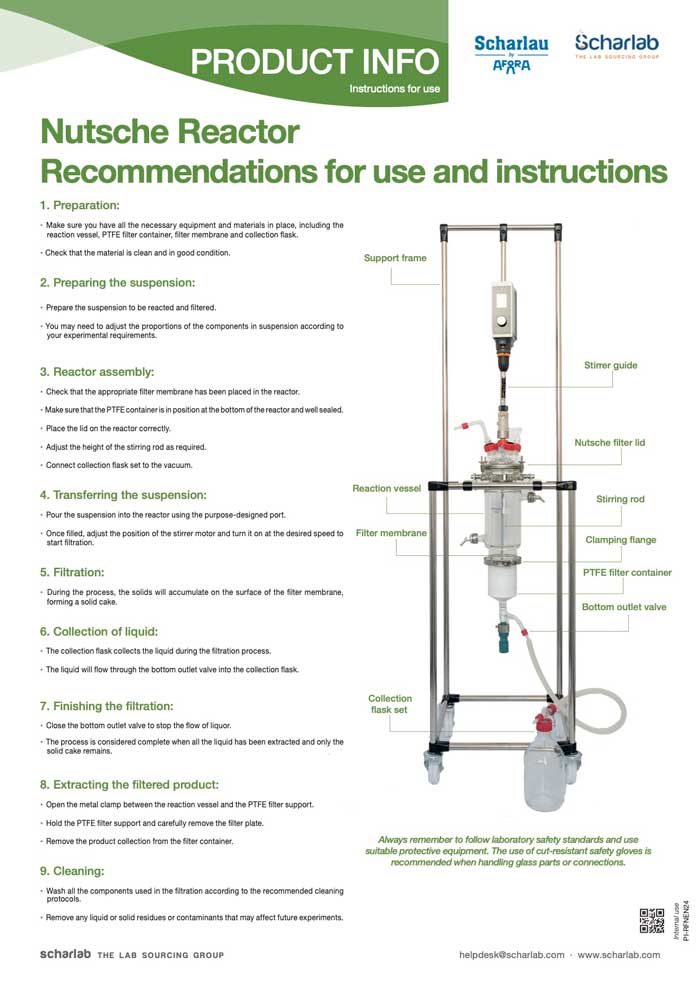

In general use, the process starts by transferring the suspension to the vessel’s filter. The solids are retained on the filter membrane, forming a cake, while the wastewater flows efficiently through the outlet valve at the bottom of the system, where it is collected in a vacuum trap flask. The filtration is complete when all the solvent has been extracted from the mixture. In addition, cakes can be removed easily by just opening the bottom plate, which in turn simplifies the process required to change the filter membrane and clean the system.

Advantages of Nutsche filters

Nutsche filters have several advantages that make them an exceptional choice for a wide range of applications:

-

- Hermetic production: The reactors guarantee a process that eliminates any risk of product loss or contamination.

- Total versatility: Our filters can be used to perform various operations in a single unit, including reaction, suspension, filtration, re-dissolution, washing and drying, which streamlines and improves the production process.

- Purity and uniformity: Nutsche filters stand out for their ability to obtain products of the highest purity and uniformity.

- Space and installation costs reduction: The ability to combine multiple operations in a single unit translates into a significant reduction in space and energy costs, optimising the investment.

- Save time: We minimise the time required for cleaning and maintenance, and filters element replacement.

In short, Nutsche filters offer a comprehensive, efficient solution that translates into higher quality, lower costs and better controlled, automated filtration in the laboratory.

For more information on these reactors or to enquire about other products or services, write to helpdesk@scharlab.com.

Related resources